When you think about packaging, most attention goes to the outer box or label. But what happens inside the box is just as important. Inserts such as partitions and dividers ensure your products arrive safely, stay organized, and present beautifully. For cosmetics, skincare, and health care products, a well-engineered insert can protect fragile containers, elevate your unboxing experience, and reinforce your brand’s attention to detail. Plus, it allows you to include two or more products in one box which may be a cost savings, a way to promote a new product or send a sample.

Why Inserts Matter

Inside-the-box engineering plays a crucial role in how products look when they reach the customer. Inserts are designed to:

- Keep fragile items like glass bottles and jars from shifting during shipping

- Protect delicate closures and pumps from damage

- Create a premium unboxing experience that feels intentional

- Present multiple products in a clean, organized manner

- Offer an additional surface for branding or product information – companies often want a larger carton for shelf visibility or to maximize content while having a physically smaller inside.

Whether it is a skincare kit, fragrance set, or supplement box, inserts give structure to the presentation while protecting your investment.

Partitions

Partitions are one of the most common types of inserts. They are often used to separate multiple items within a single package. For example, cosmetic and health care brands rely on partitions for products like serums, lotions, or oils packed in glass bottles.

Example:

A nutraceutical brand packaging a 3-bottle supplement set used a paperboard partition to hold each bottle snugly in place. The structure kept the bottles from clinking together during shipping and allowed the top of each cap to remain visible through a window cutout. This design not only protected the glass but also created a clean, retail-ready presentation.

Partitions can be made from paperboard, microflute, or other premium paper stocks. They can be left blank or printed to match your brand. A printed partition with brand colors or a simple logo turns a purely functional piece into a visual asset.

Dividers

Dividers provide larger compartments or custom-shaped cutouts designed to fit the exact dimensions of your product. They can be simple rectangular sections or fully contoured trays that cradle each item.

Example:

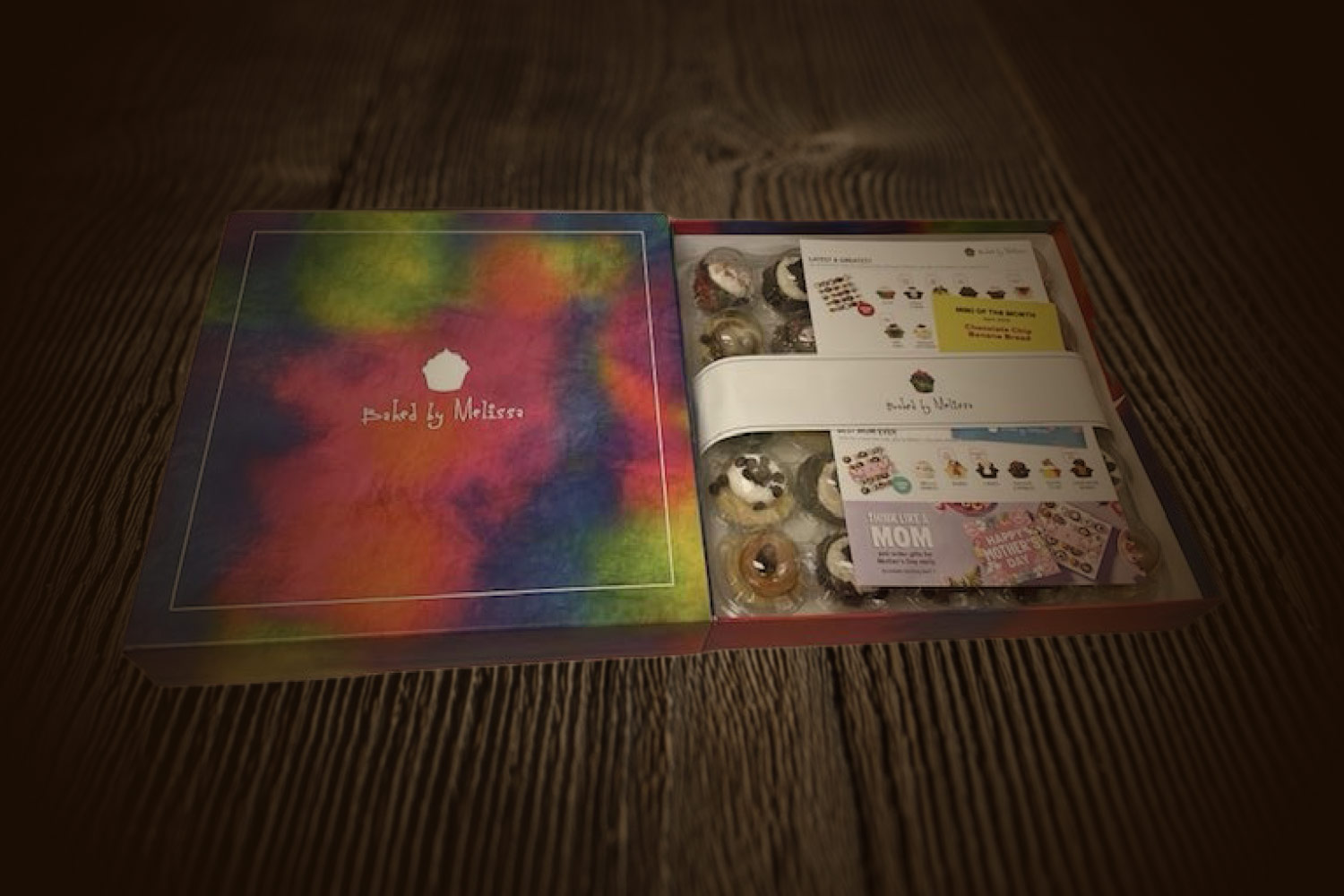

A skincare company launching a “hydration trio” used a white SBS divider with die-cut shapes to hold a cleanser tube, serum bottle, and moisturizer jar. Each product fit precisely into its compartment, allowing for perfect alignment under the window on the outer carton. The divider’s clean lines and snug fit gave the entire package a premium feel.

Another health and beauty brand used a divider to secure a facial roller next to a serum bottle. The die-cut opening matched the roller’s handle shape, ensuring it stayed centered and secure during shipping.

Dividers not only prevent movement but also enhance visual appeal. When a customer opens the box, everything appears neatly arranged and thoughtfully designed.

Branded Inserts

Inserts can go beyond protection. Custom printing allows brands to communicate directly with customers during the unboxing moment. Some cosmetic companies print product instructions, ingredient highlights, or QR codes on the insert surface. Others include short brand messages or thank-you notes printed in matching colors. This extra touch extends your brand story while keeping all printed components integrated and professional.

Benefits of Using Partitions and Dividers

- Product Protection: Reduces damage from impact or movement during transit.

- Professional Presentation: Ensures every component stays aligned and looks intentional.

- Brand Enhancement: Adds perceived value with custom printing and color matching.

- Reduced Returns: Fewer damaged products mean happier customers and lower replacement costs.

- Additional marketing area: Companies may use a larger carton than the product for a variety of reasons, including branding, messaging and visibility.

Frequently Asked Questions On Custom Inserts

What materials are best for cosmetic or health product inserts?

Most brands use paperboard, chipboard, or microflute.

Can inserts be customized for different product sizes?

Yes. Inserts are always designed around the exact dimensions of your product. Ritter’s packaging engineers create die lines that fit your bottles, jars, or applicators perfectly.

Can I see a prototype box with my insert?

Yes. Here’s more about box prototyping (link to blog post about Box Prototyping from Oct. 16, 2025)

Can inserts include graphics or printing?

Absolutely. Inserts can feature brand logos, instructions on use, QR codes, or color-matched backgrounds for a complete branded presentation.

Are inserts only for premium products?

No. Even cost-conscious brands benefit from inserts. They improve product safety, reduce damage, and make a strong first impression.

Custom Inserts at

Ritter’s Printing & Packaging

At Ritter’s Printing & Packaging, we engineer custom inserts that combine form and function. Whether you need partitions for pharmaceutical products or dividers for a cosmetic kit, we can help your products arrive safely and look their best from the moment the box is opened.

If you’d like to discuss custom inserts for your next project, call us at 954-771-7204 or contact us online today.